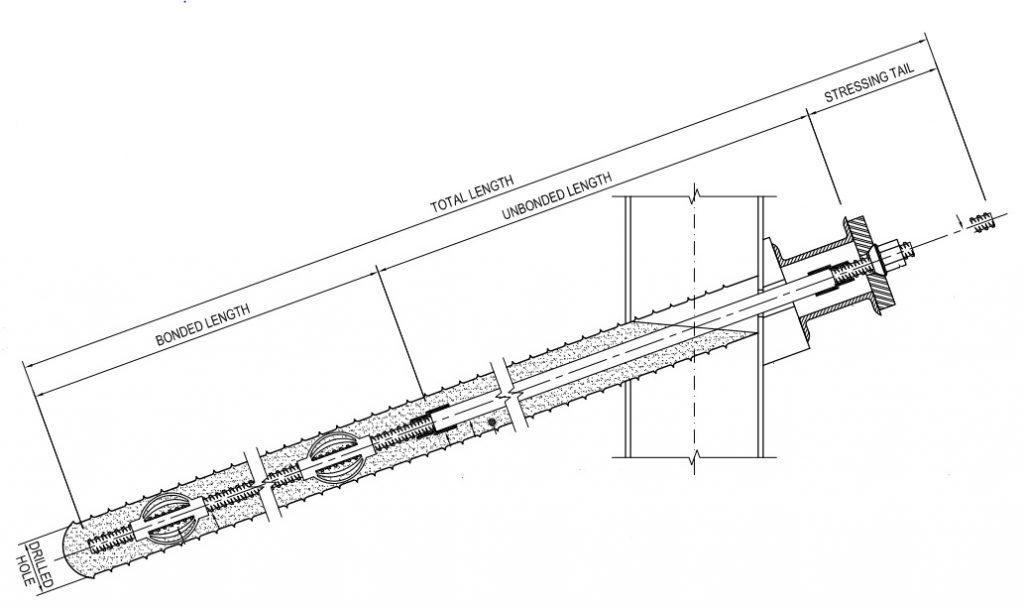

The Creek Protection Project consisted of several phases of work including increasing the hydraulic capacity of the creek. Coastal installed permanent rock anchors within a post and panel floodwall positioned in the creek. In order to resist the design load, an additional bar tendon rock anchor was installed between the existing multi-strand rock anchors. This bar tendon rock anchor has capacity greater than or equal to the capacity of the two (2) existing multi-strand rock anchors and will resist the design load if the existing anchors fail. Anchor construction commenced with a detailed review and understanding of the anchor construction specification and project drawings. Dimensions and properties of permanent materials including all-thread-bar, plates and grout that are common for bar anchors were determined. Additionally, for rock bonded anchors, the minimum embedment into rock, referred to as the bond length, was also required.